MECHATRONIC MOLDS ARISING CONNECTED THROUGH INTERNET. Mechatronic molds are now a reality!. The project EMOLDE , coordinated by FEAMM, has failed to demonstrate that the conditions of pressure and temperature inside a mold in the injection process, captured by sensors can be monitored and controlled from a computer located anywhere.

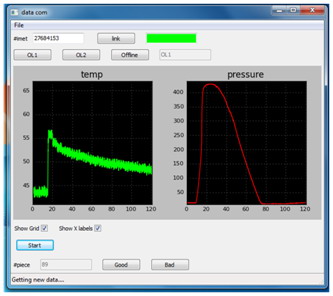

The project EMOLDE , funded by the ERDF in the call Avanza Plan 2010, has introduced a technological improvement in the injection molding process, developing a mechatronic system that reads the signals from the pressure and temperature sensors inserted into the mold and sends the signal to a computer that has an interface and software specially designed to treat such information. The mechatronic system, created by ELEDA CUMSA, S.A. for the project, based on the information of I-met (Part dater or marker), and the information of pressure and temperature sensors. This system is capable of sending, in real time, credible signal what is occurring within the mold during the injection process of a plastic part, in addition to identifying each of the parts produced through the I-met.

The project EMOLDE , funded by the ERDF in the call Avanza Plan 2010, has introduced a technological improvement in the injection molding process, developing a mechatronic system that reads the signals from the pressure and temperature sensors inserted into the mold and sends the signal to a computer that has an interface and software specially designed to treat such information. The mechatronic system, created by ELEDA CUMSA, S.A. for the project, based on the information of I-met (Part dater or marker), and the information of pressure and temperature sensors. This system is capable of sending, in real time, credible signal what is occurring within the mold during the injection process of a plastic part, in addition to identifying each of the parts produced through the I-met.

The interface and software developed by PLASTIA for the project, allowing the improvement of the production system offering complete traceability of the manufactured parts, predicting the quality of them based on advanced statistical models and artificial intelligence systems. The system allows manufacturers of plastic components to improve productivity, providing confidence intervals, and can be interpreted as deviations in the quality of manufactured parts, offering a solution and a real asset to traceability.

The interface and software developed by PLASTIA for the project, allowing the improvement of the production system offering complete traceability of the manufactured parts, predicting the quality of them based on advanced statistical models and artificial intelligence systems. The system allows manufacturers of plastic components to improve productivity, providing confidence intervals, and can be interpreted as deviations in the quality of manufactured parts, offering a solution and a real asset to traceability.

The Technological Institute of Castilla y Leon has created a tool based on virtual reality techniques used to display the different results obtained in the project. The tool allows various viewing levels and free access to documentation and user interaction within it. Project can be accessed at the following Web address: http://www.itclimasd.org/Realidad-Virtual/Proyectos-Investigacion/emolde.asp

The Technological Institute of Castilla y Leon has created a tool based on virtual reality techniques used to display the different results obtained in the project. The tool allows various viewing levels and free access to documentation and user interaction within it. Project can be accessed at the following Web address: http://www.itclimasd.org/Realidad-Virtual/Proyectos-Investigacion/emolde.asp

In EMOLDE, ELEDA CUMSA participated as mechatronic system developer, PLASTIA as software developer, MECANICAS SOLÉ as sensorized mold maker, and ROBERT BOSCH SOGEFI GASOLINE FILTRATION SYSTEMS as end users, the Technological Institute of Castill y Leon as virtual model developer. The FOUNDATION ASCAMM as technical coordinator and FEAMM as overall project coordinator.

Demonstration video EMOLDE system:

EMOLDE: MOULDS mechatronic CONNECTED THROUGH INTERNET.

The project aims to introduce a new technological improvement in injection molding processes. Want developing mechatronic systems and thus use, embedded systems in these processes. Thus aims to make the molds are no longer passive elements to achieve an improvement in the overall efficiency of the production cycle of plastic parts.

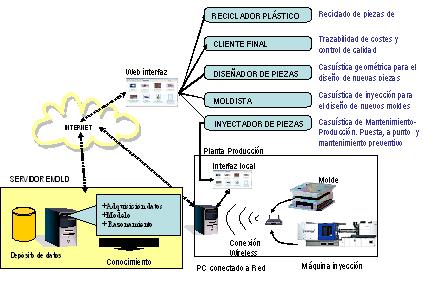

With EMOLDE, the tools will become active elements connected with the process and integrated knowledge. And all elements of the process can be monitored and corrected in real time. In short, the tool will be the connection to the flow of knowledge, and the knowledge built into these molds smart to store the know-how achieved by technical and exploit this knowledge more efficiently, in conclusion, is to get increasingly intelligent molds.

The project was born EMOLDE how natural extension EMOLDE European project. With EMOLDE, FEAMM wants to develop its own technology for the control and monitoring of injection molding process for the collective potential, without having to rely on foreign technology for the automation and optimization of same.

The project consists in the implementation of two molds intelligent industrial conditions. This would require developing the eBox, the configurator or interface with user and a knowledge based system (CBR). The aim to achieve can be divided into the following sub-objectives: 1 – To design molds equipped with sensors and mechatronic mechatronic devices, so that the mold will become “intelligent” agents of the plastic supply chain. It would take temperature and pressure sensors and obtain information from electronic scoreboard or datalog. 2 – To integrate these networks mechatronic molds, these molds so “smart”, the system will be managed by an embedded system and send the information to the different chain actuators plastic injection process. 3 – Develop a Knowledge Based System (CBR), so that the knowledge embedded in these molds retain smart and will optimize the efficiency of the new processes and the implementation phase of new processes and the design of new molds. The knowledge gained can be provided to any agent of the supply chain from collected plastic Networking: client end, designer pieces, designers and builders of molds, injectors, secondary processes, etc.. 4-Creating a tool based on virtual reality techniques (RV) documentary dynamic management online access. The application will display different results being obtained in 3D. The following diagram gives an overview of the different parts of the project:

EMOLDE The project is funded by the European Regional Development Fund (ERDF) within the call of PLAN AVANZA 2010.